-

Where is the assembly line for dispensing, soldering, and sealing circuit boards used

2025-07-29The assembly line for dispensing, soldering, and sealing circuit boards is a key equipment combination for achieving automated production in the electronic manufacturing industry. It is mainly used to complete core processes such as assembly and protection of circuit boards (PCBs), and its application scenarios cover various fields that require large-scale and high-precision electronic component p

-

In which industries are desktop dispensing platforms applied

2025-07-22The desktop dispensing platform has the characteristics of small size, simple operation, and high precision, and is widely used in multiple industries such as electronics, automotive, optoelectronics, and medical. The specific details are as follows:

-

What are the applications of multi station integrated machines for dispensing and soldering detectio

2025-07-15The multi station integrated machine for dispensing and soldering detection is an automated equipment in the electronic manufacturing industry that integrates functions such as dispensing, soldering, and quality inspection. It achieves efficient and precise assembly of electronic components through multi station collaborative operations. Its application scenarios widely cover consumer electronics,

-

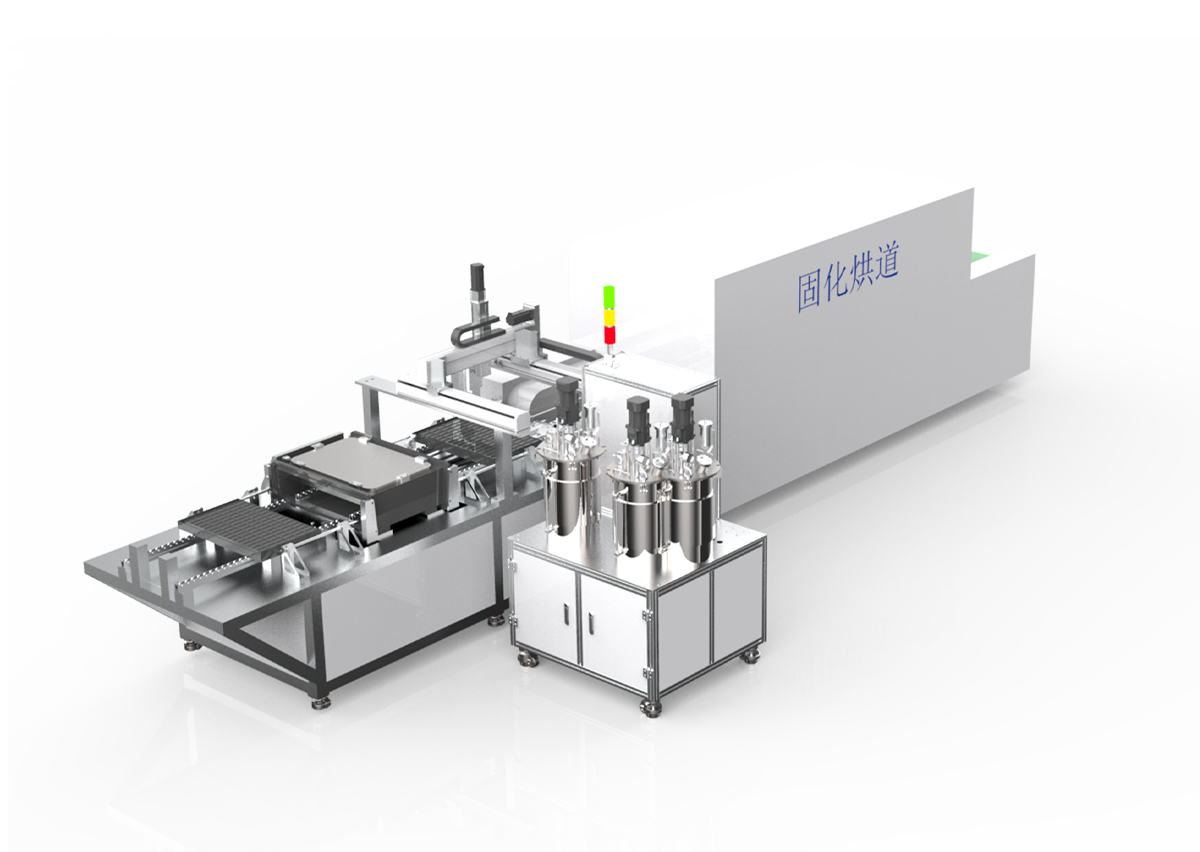

In which industries is the sealing vacuum defoaming curing assembly line used

2025-07-08The vacuum defoaming and solidification assembly line for sealing is widely used in industries that require high sealing quality, mainly including the following fields: 1. Electronic information industry: In chip packaging, bubbles in the bottom filling adhesive can be eliminated to prevent chip cracking caused by thermal stress. For MEMS sensors, we can provide pore free packaging to ensure stab

中文

中文 英文

英文

WeChat official account

WeChat official account

Scan your phone once

Scan your phone once

Wechat ID:

Wechat ID:

wechat

wechat

contact

contact

phone

phone